The 1946 Chevrolet Truck Restomod Build

To celebrate our upcoming 20 years of service (2029) and to showcase our passion for commercial vehicles and engineering, we have decided to do a restomod on a 1946 Chevrolet pick-up truck.

We are going to use a Chevrolet Corvette C6 (2005-2013) drivetrain and build a new chassis inhouse on our Celette jig. We will be documenting this build with regular updates on our progress as time allows.

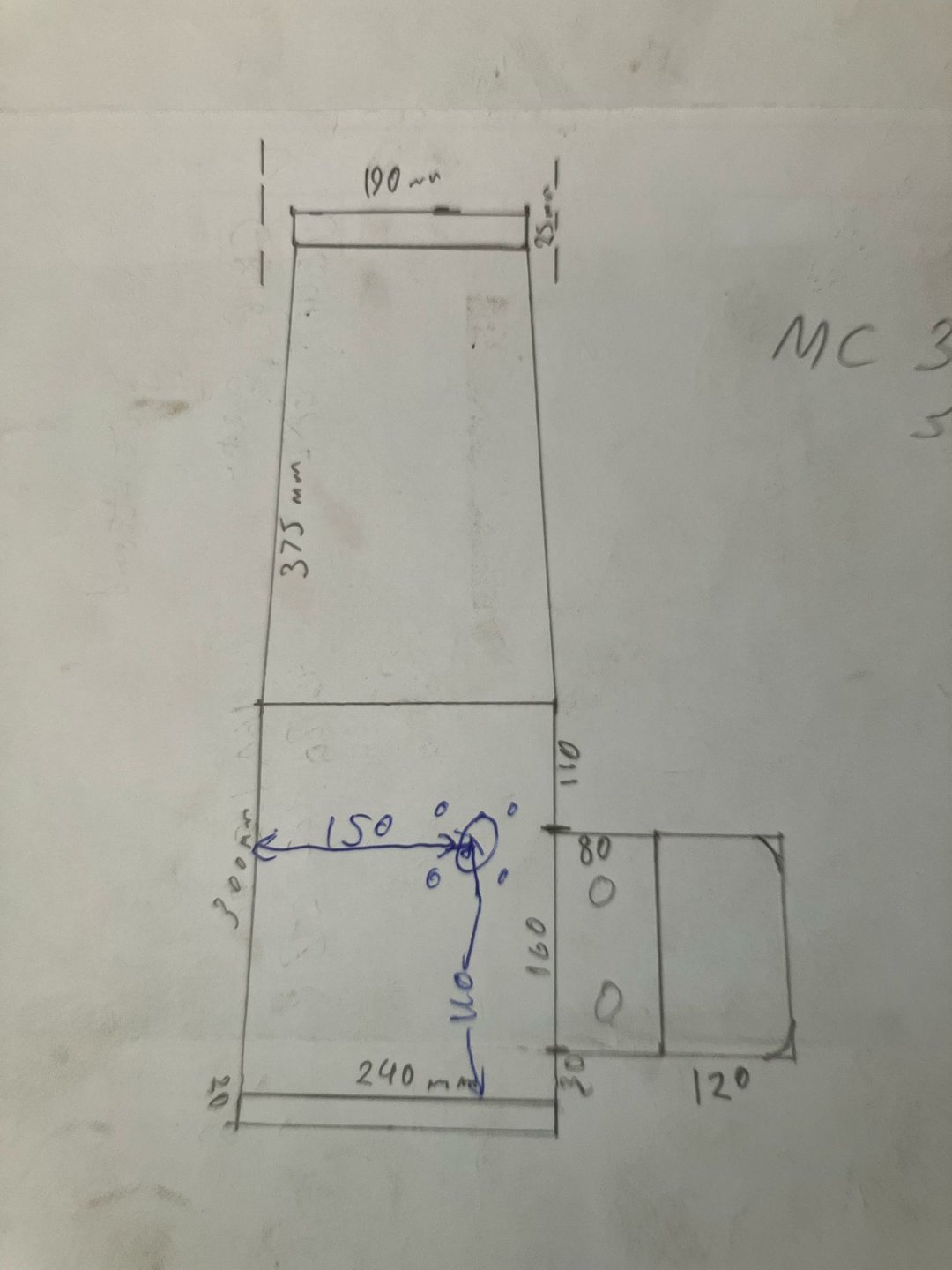

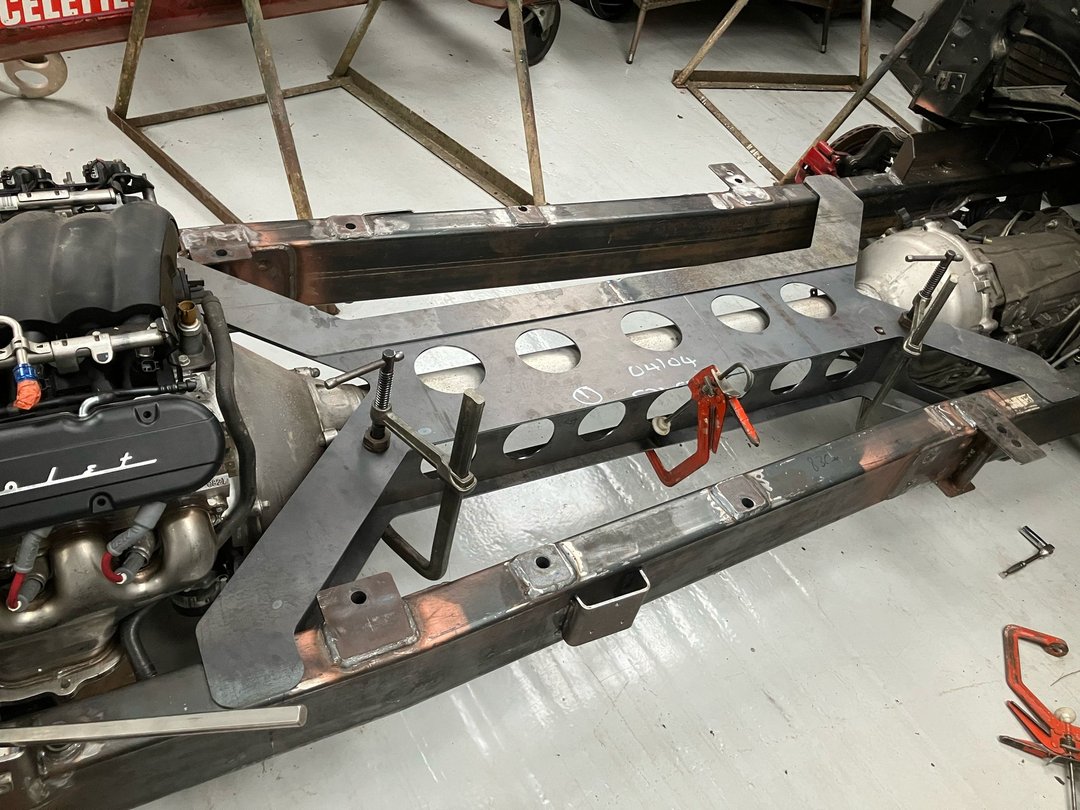

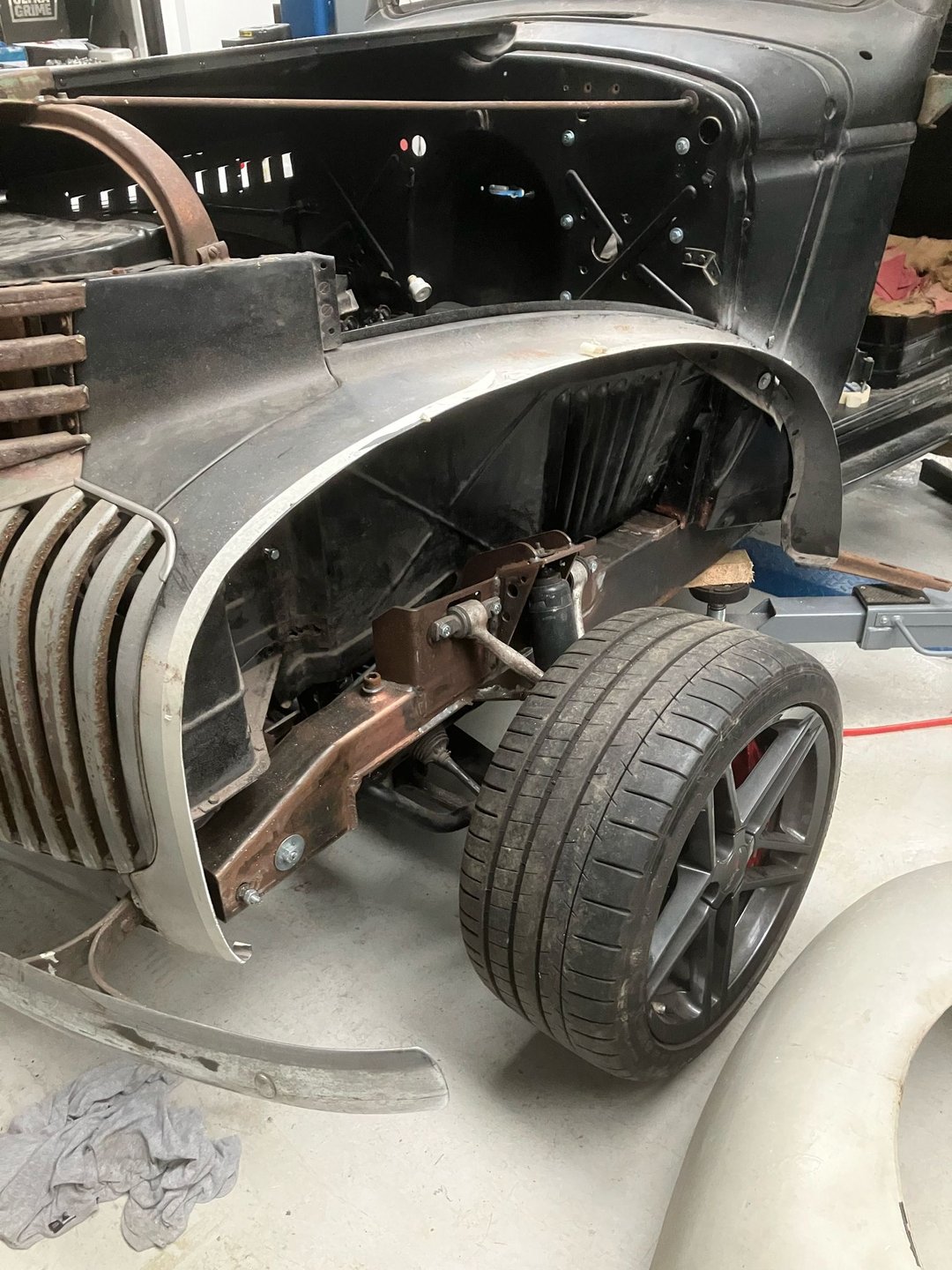

Neither would any of the suspension, steering or brakes. We decided to utilise the full drivetrain and suspension from a C6 Corvette, a suitable donor car was found and promptly removed of all the required parts the next stage involved building the jigs for the Corvette suspension pick up points so they could be replicated on the new chassis. Two 160 by 80 by 4 mm box sections were ordered to serve as the main chassis rails chosen as they are similar in specification to the original Corvette frame the new sections needed to be “swan necked” to give the correct widths for the front and rear Corvette subframes to fit, after lots of measuring and maths the top height of the frame rails was determined to give the finished truck the desired ride height, with this completed the rails could have the subframe bolts pick up points bolted to the jig and welded to the them.

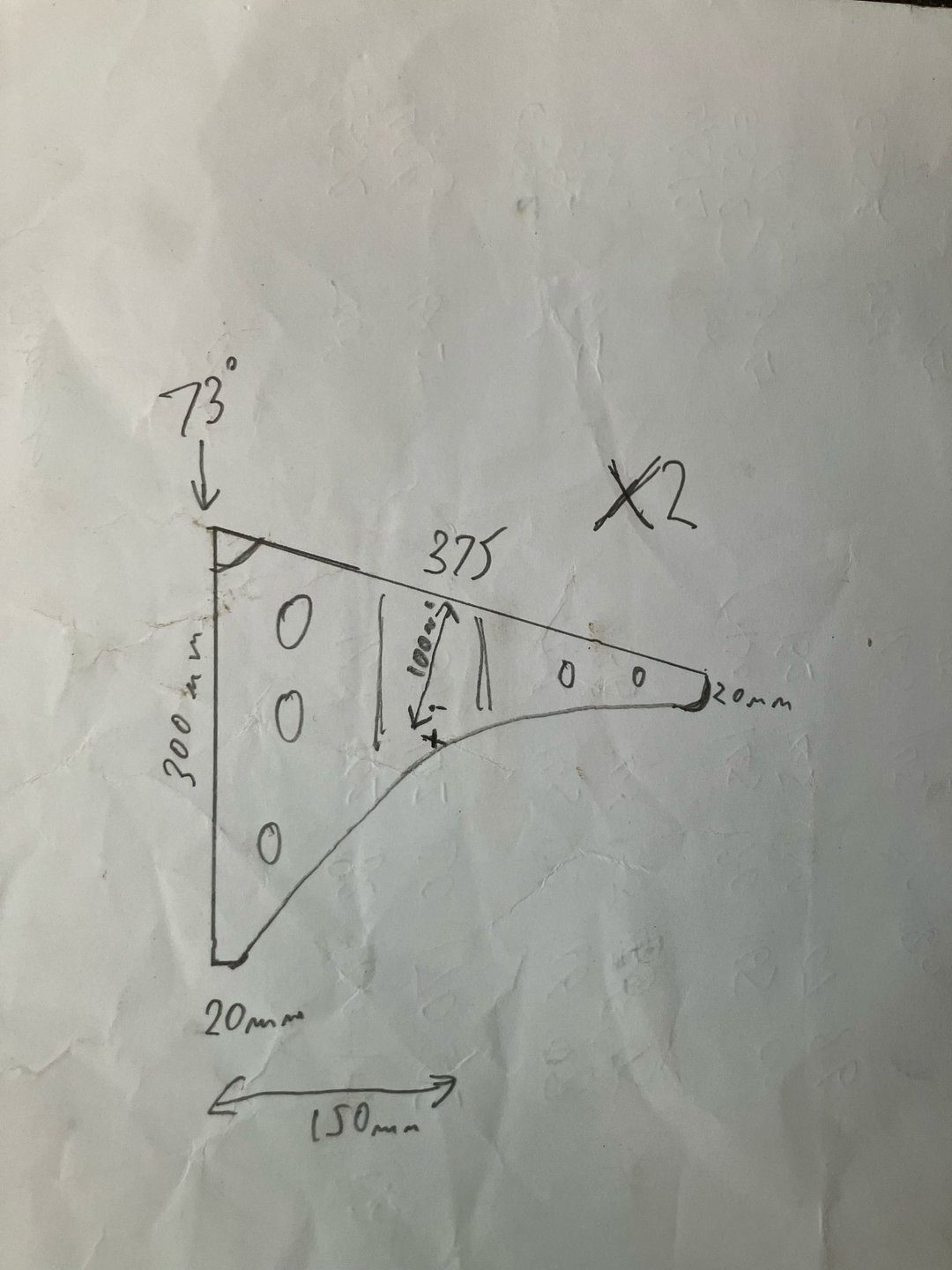

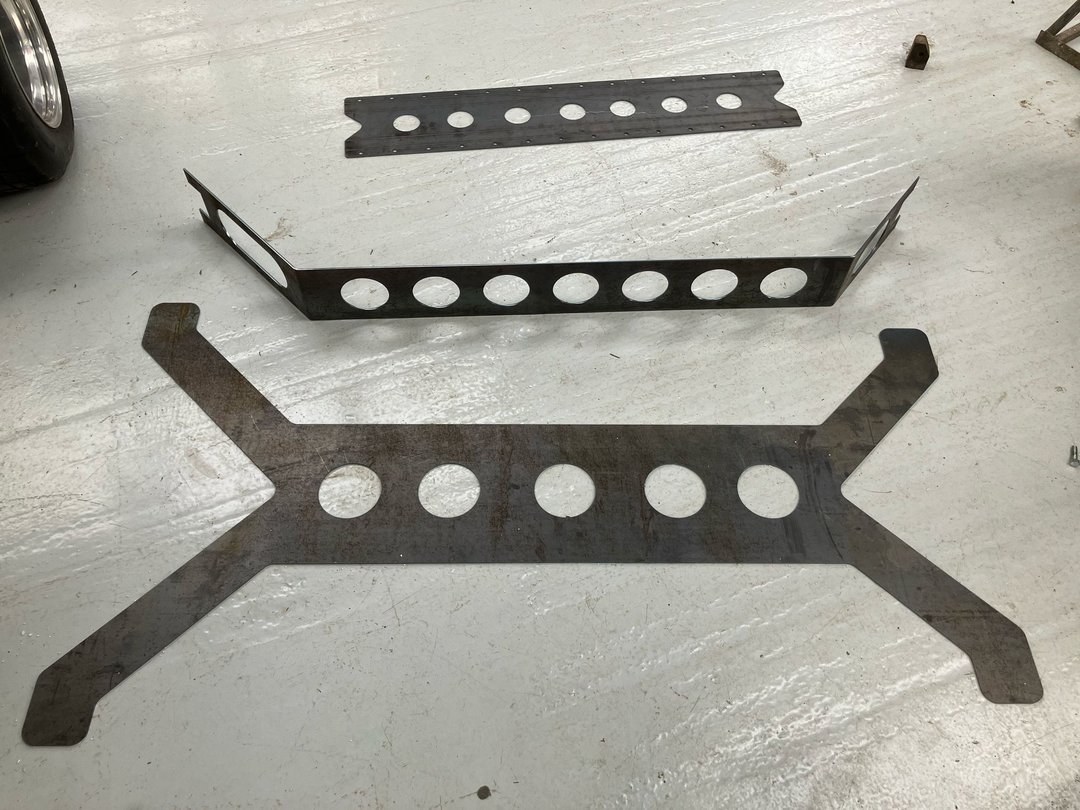

Next up was the upper suspension points so with both rails back in the jig all the measurements could taken and parts drawn up we used 6 mm plate for these and had it all plasma cut out and folded these new parts were bolted into the jig and welded into position on the frame rails. The two rails (still independent at this stage for ease of movement) were placed back in the subframes all suspension attached so for the first time it could roll around on its wheels! Once everything was evaluated and proven to work the two rails returned to the jig to become one this involved 3 cross members and an X bone design which will give the truck the torsion rigidity that is required the X brace was designed to have a centre section that unbolts so that the torque tube can be removed from underneath. With the chassis at this stage all of the suspension, engine, and transaxle from the C6 was fitted to it and the 1946 cab and front panels fitted.

Various brackets were made to allow us to fit the rear bed which has been shortened by 240 mm to allow for the Corvettes shorter wheelbase, it was either shorten the truck body or extend the torque tube which is doable but it was decided that the suspension geometry was built around that wheelbase so best to leave as GM intended, with any project like this wheel choice needs to be made fairly early on, with this project there were two choices keep the base model narrow body set up or use the Grand Sport/Z06/ZR1 widebody wheel option the later was chosen which required the body to be widened to accommodate the extra width this will add to the hot rod look giving the truck 275/35/18 front and 325/30/19 rear tyres using OEM offsets, this also allowed the fitment of the bigger ZO6 brakes.

GM, as does any manufacturer, spends millions of dollars with near endless resources and many talented engineers so why not take advantage of all that? All we are essentially doing is making a big bracket to bolt a Corvette drivetrain to a 1946 Chevy pickup body. Next up now it’s proven that it works is to carry on with the dry build to integrate the two together so that everything functions, first up is steering and pedals again a new pedal box was measured up, drawn out, cut out, folded and welded using the Corvette alloy brake pedal and DBW throttle pedal! The steering column is mounted two inches to the left of its original position (but with a 4 inch smaller diameter steering wheel the offset is not noticeable in the cab) this allows the steering shaft and UJ’s to clear the Left Bank of the V8 engine (the original engine was straight 6) next on the agenda is fuel tank, exhaust system and gear linkage.

Watch this space!

With special thanks to www.budfab.com for the metal cutting work.